1. Oven for Powder Coating Components and Technology

A modern Oven for Powder Coating cures thermoset powders into durable finishes using precise heat control. Core components include insulated chambers (ceramic-fiber or steel), heating systems (electric, gas, infrared), airflow fans, and IoT-enabled thermostats. Advanced 2025 models feature AI-driven temperature profiling and carbon-neutral energy options like solar integration.

2. Applications of Powder Coating Ovens

These ovens are vital in automotive (EV battery casings, alloy wheels), aerospace (engine components), and consumer goods (appliances, furniture). DIY enthusiasts use compact ovens for motorcycle parts or custom décor. High-temperature models (up to 450°F) also cure coatings on heat-resistant plastics for electronics.

3. Powder Coating Oven Price Guide 2025

- Benchtop units

: 2,800–6,500 for small workshops.

- Industrial batch ovens

: 25,000–75,000 with conveyor systems.

- Hybrid solar-electric models

: Priced 15–20% higher but reduce energy costs by 40% over five years.

4. How to Operate a Powder Coating Oven Safely

Preheat to the powder manufacturer’s specified temperature (typically 350°F–400°F).

Use heat-resistant racks to ensure even airflow.

Set timers to prevent overcuring; most coatings require 10–25 minutes.

Cool parts gradually to avoid thermal shock.

Always wear PPE (gloves, masks) and ensure ventilation to eliminate fumes.

5. Choosing the Right Powder Coating Oven

- Size

: Match internal dimensions to your largest part (e.g., 4'x4' for car rims).

- Heating type

: Infrared for speed, convection for uniformity.

- Certifications

: Prioritize UL 508A, CE, or ISO 9001 compliance.

- Upgradability

: Opt for 2025-ready ovens with modular IoT sensors.

6. Safety Tips for Powder Coating Ovens

Install fire suppression systems and CO detectors.

Avoid overcrowding racks; maintain 2-inch gaps between parts.

Inspect electrical wiring monthly to prevent short circuits.

Use non-flammable insulation (e.g., mineral wool) in DIY builds.

7. Design Efficiency in 2025 Powder Coating Ovens

Modern ovens prioritize sustainability:

- Recycled materials

: 30% of new ovens use reclaimed steel.

- AI optimization

: Reduces energy waste by 25% via predictive curing cycles.

- Modular designs

: Allow easy integration of UV-curing modules for faster processing.

8. FAQs on Powder Coating Ovens

Q: What oven types suit automotive powder coating?

A: Conveyor ovens with 400°F+ capacity and rapid cooling zones.

Q: How often should I maintain my powder coating oven?

A: Clean filters weekly, recalibrate sensors quarterly, and replace heating elements every 3–5 years.

Q: Can powder coating ovens handle large metal parts?

A: Yes—industrial models support parts up to 25 feet long (e.g., truck frames).

Q: Are solar-compatible ovens cost-effective?

A: 2025 models cut energy bills by $1,500+ annually, with ROI in 2–3 years.

Q: What certifications ensure oven safety?

A: UL 508A for electrical systems and ISO 9001 for manufacturing standards.

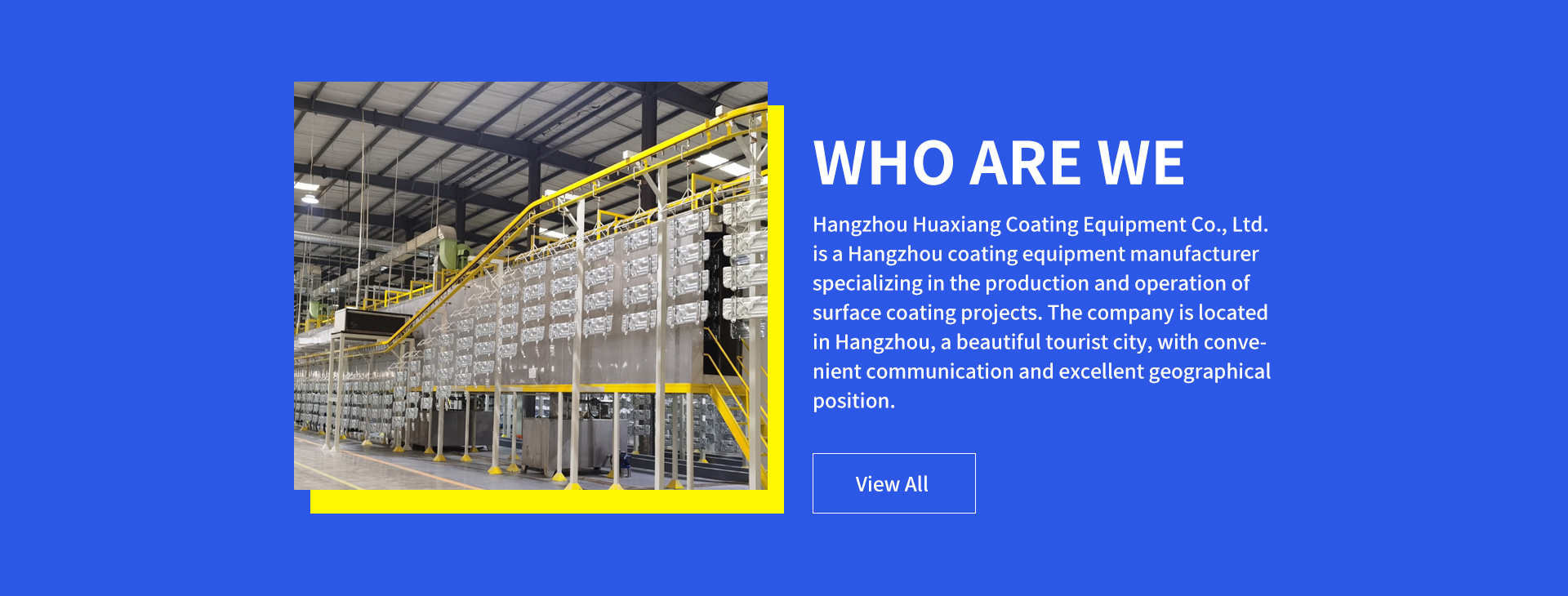

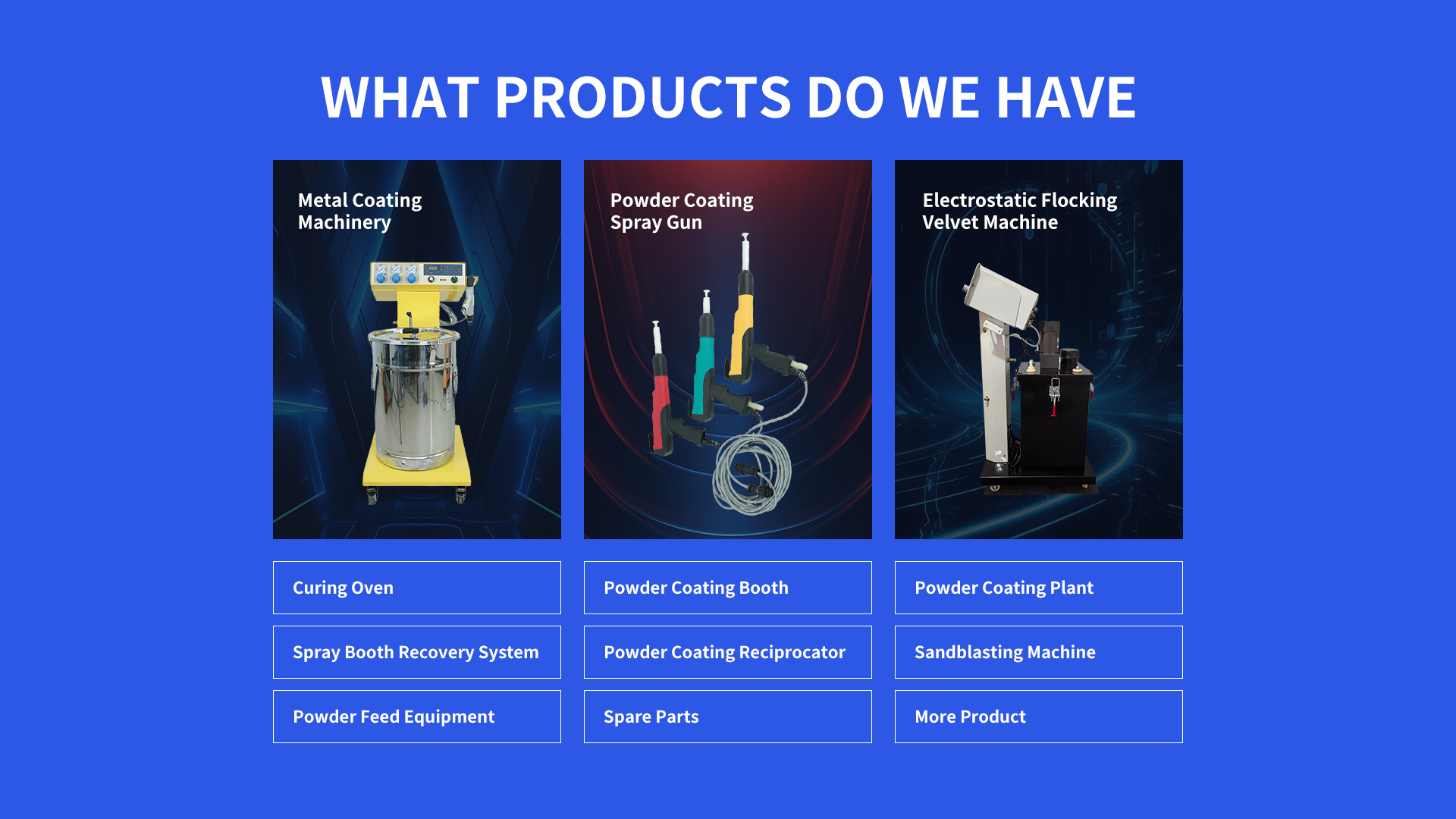

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com