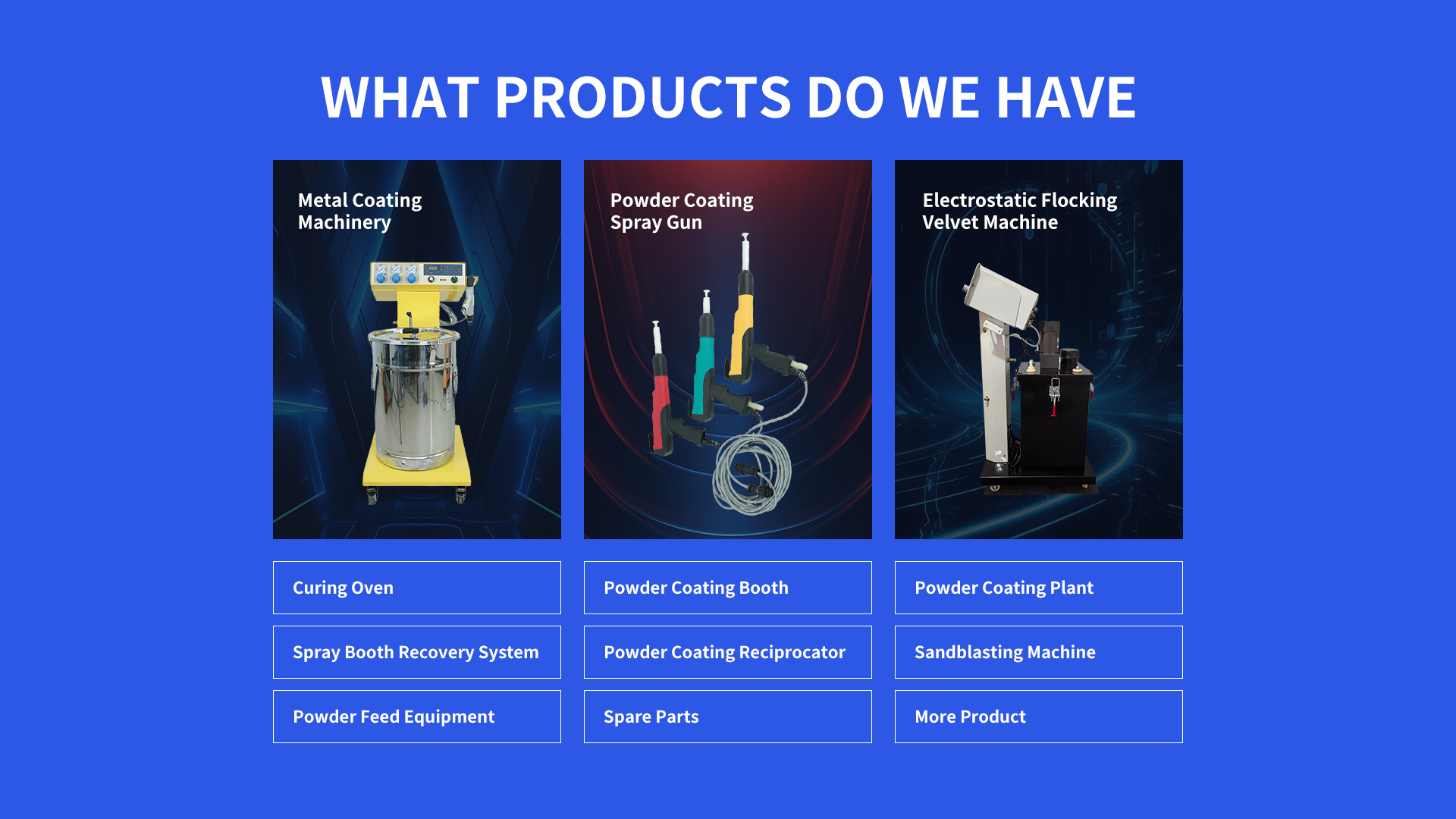

1. Industrial Powder Coating Spray Gun Overview and Components

An Industrial Powder Coating Spray Gun is a precision tool designed to apply electrostatic powder coatings evenly onto metal or non-metal surfaces. Key components include a powder hopper, electrostatic generator, nozzle, trigger mechanism, and grounding cable. The gun uses electrostatic charge to attract powder particles to the target surface, ensuring minimal waste and uniform coverage. Modern models feature adjustable airflow, voltage controls, and ergonomic designs for enhanced usability in industrial settings.

2. Applications of Industrial Powder Coating Spray Gun

Industrial Powder Coating Spray Guns are essential in automotive manufacturing, aerospace, furniture production, and machinery coating. They are ideal for coating engine parts, aluminum frames, appliances, and architectural components. Their versatility allows use on materials like steel, aluminum, and plastics, providing durable, corrosion-resistant finishes.

3. Pricing of Industrial Powder Coating Spray Gun

Prices for Industrial Powder Coating Spray Guns range from 500forbasicmanualmodelsto5,000+ for automated, high-volume systems. Entry-level guns suit small workshops, while advanced models with digital controls and higher transfer efficiency cater to large-scale industries. Factors like brand reputation, durability, and technical support influence costs.

4. Proper Usage of Industrial Powder Coating Spray Gun

Ground the workpiece to ensure electrostatic adhesion.

Adjust voltage (typically 30–100 kV) and airflow based on powder type.

Hold the gun 6–12 inches from the surface and apply in smooth, overlapping strokes.

Clean the gun after use to prevent clogging.

Regular maintenance, such as replacing worn nozzles, ensures consistent performance.

5. How to Choose the Right Industrial Powder Coating Spray Gun

Coating Type: Match the gun to powder materials (e.g., epoxy, polyester).

Production Scale: Opt for automated guns for high-throughput tasks.

Ergonomics: Prioritize lightweight designs for operator comfort.

Efficiency: Select guns with 95%+ transfer efficiency to reduce waste.

Reputable brands like Wagner and Nordson offer reliable options.

6. Safety Precautions for Industrial Powder Coating Spray Gun

Wear PPE (respirator, gloves, goggles) to avoid inhaling powder.

Ensure proper ventilation to prevent explosive dust accumulation.

Regularly inspect grounding systems to prevent electrostatic hazards.

Store powder in sealed containers away from moisture.

7. Design Rationale of Industrial Powder Coating Spray Gun

Industrial Powder Coating Spray Guns prioritize precision, efficiency, and operator safety. Electrostatic technology minimizes overspray, while ergonomic grips reduce fatigue. Modular designs allow easy part replacement, and corrosion-resistant materials extend lifespan in harsh environments.

8. Q&A on Industrial Powder Coating Spray Gun

Q1: What is the ideal voltage setting for an Industrial Powder Coating Spray Gun?

A: Adjust between 50–80 kV for most powders; consult manufacturer guidelines.

Q2: Can these guns apply multiple powder colors without cross-contamination?

A: Yes, thorough cleaning between color changes prevents mixing.

Q3: How does electrostatic application improve powder coating efficiency?

A: Electrostatic charge attracts powder to surfaces, reducing waste by up to 70%.

Q4: Are these guns compatible with high-temperature powders?

A: Yes, but ensure the gun’s materials withstand curing temperatures.

Q5: What maintenance extends an Industrial Powder Coating Spray Gun’s lifespan?

A: Clean after each use, replace worn parts, and store in dry conditions.

This guide equips professionals with critical insights into Industrial Powder Coating Spray Guns, ensuring optimal performance, safety, and cost-effectiveness in coating operations.

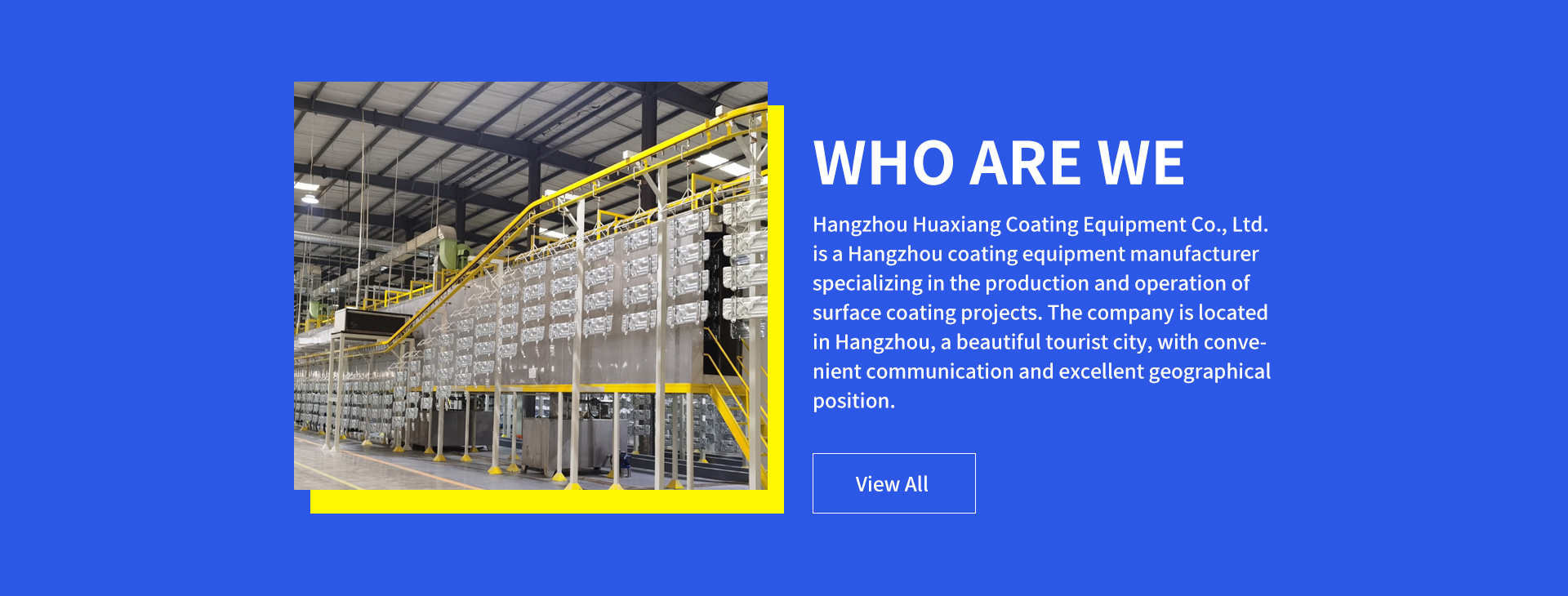

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com